about

About Us

Xuzhou Elephant Electric Co., Ltd is a professional manufacturer and exporter of transformer.

1.9 years of manufacturing experience and 2 Years exporting experience

2. Great technician Team with innovation and improvement alibilties

3. Zero accident record and good feedback from buyer

4. Best price offered with special discount to develop oversea market, high quality you can enjoy.

5. Fast response with sales and after-sale service

6. Welcome agent or distributor all over the world with most attractive profit and long last cooperation partnership.

Production

We boasts modern factory buildings and top-notch manufacturing equipment, coupled with advanced management practices and technologies.

Quality

With a commitment to strict quality control measures at every stage from design to installation,our products are guaranteed to deliver superior quality.

Service

We will leverage our DXCM brand, capital, technology, and market advantages to provide high-quality and technologically advanced products and services for the majority of users.

Product Advantage

● Main technical indicators have reached the latest advanced level of similar products athome and abroad

The accuracy of manufacturing has reached Level 4 with the stable performance. More reliable and stable:take the advanced squeeze casting process with the higher density materials.The mechanics performance isupgraded to at least 20% higher than the lowpressure casting.

● High efficiency and low energy consumption

Perfectly combining the new high-precision spiral gears and the hardened helical gears, the transmissionefficiency reaches up to 96%.

● Low temperature rise

Running with rated load. the oil temperature is measured according to 40% of the working time. Lowertemperature of oil can extend the aging of oil seal; the new design for the sealing of shaft and the uniquecontrol system can effectively solve the leakage of oil which happens regularly in the market.

● Tooth profile meshing design is more reasonable

When the motor is in the state of power consumption or power generation, the reducer can run normally andis not restricted by the dynamic direction, which can effectively solve the defect of broken teeth of quasi-hyperbolic gear in the market.

● Low vibration, shock resistance, stable operation

Adopt two-stage transmission. The first stage adopts a new type of helical gear friction transmission. Thegear pair has the characteristics of low noise, consistent transmission stability with the traditional turbine pairand good shock absorption. Helical gear speed has a great influence on vibration and noise, so helical geartransmission is put in the second stage.

● Long service life and low maintenance cost

Take SC200 double drive as an example. The cage weight is 2000kg, the load is 2000kg, and the speedis 33m/min. Equipped with two 13kw motors,100% load /20 minutes-50% load /16 minutes-25% load /24minutes-> equivalent load 72% in any 1-hour interval during the daily running time, the service life of thereducer is up to 45,000 hours.

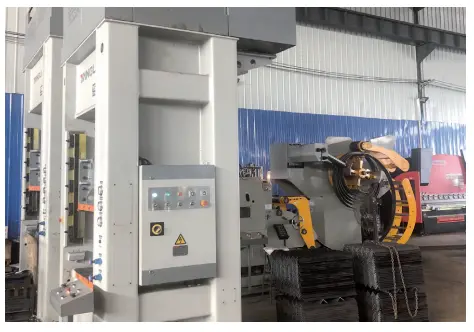

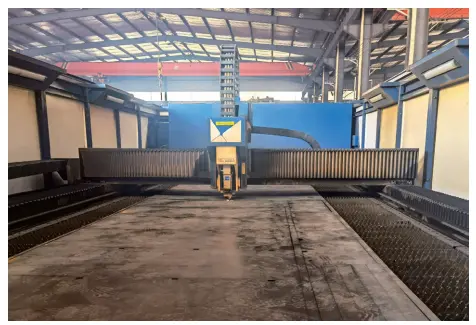

Factory Equipment

Gantry machining center

CNC bending machine

Main rotary tube coaxial special machine

CNC pipe cutting machine

CNC automatic stamping line

Standard section welding robot

CNC sawing machine

Laser fiber cutting machine (internal)

Certificate